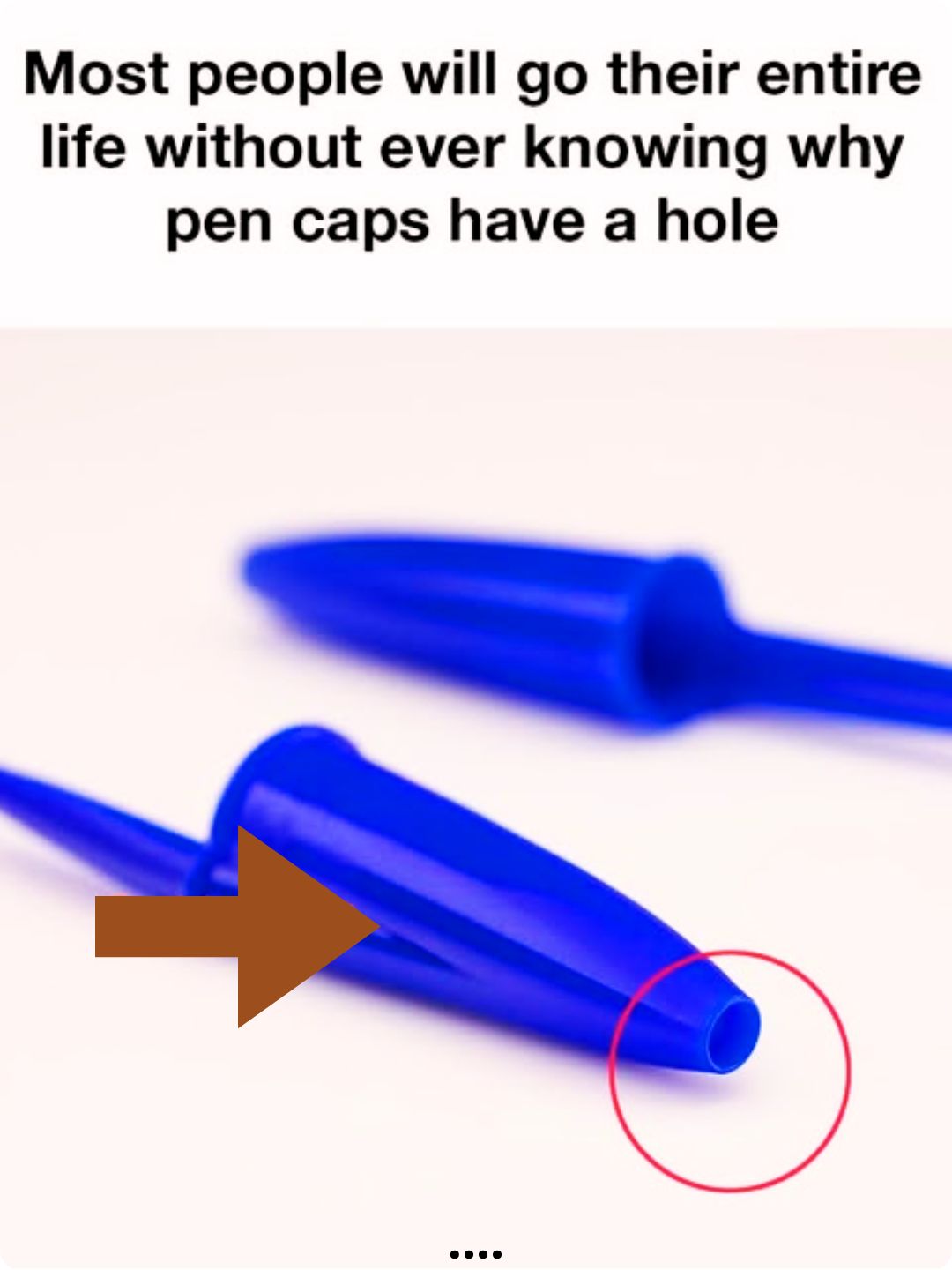

This safety feature became standard after international safety regulations , such as those from the International Organization for Standardization (ISO) , required that pen caps be either:

Too large to swallow

Ventilated (with a hole)

Or made of a soluble material

Today, many pen manufacturers follow ISO 11540 , which specifies that pen caps must allow a minimum airflow of 8 liters per minute through the hole — enough to sustain breathing in an emergency.

Fact: In the 1990s, a tragic incident involving a teenager who choked on a pen cap led to widespread adoption of this safety standard.

2. Pressure Equalization: Keeping Ink Flowing Smoothly

Have you ever uncapped a pen and found ink leaking out — or worse, dried up inside?

The hole helps prevent this by equalizing air pressure inside the pen. When a pen is capped, changes in temperature, altitude, or humidity can create pressure differences between the inside and outside of the barrel.

Without a way for air to escape or enter:

Pressure can build up and force ink to leak

A vacuum can form, making it harder for ink to flow

The tiny hole acts as a pressure release valve , allowing air to move in and out gently. This keeps the ink reservoir stable and ensures a smooth, consistent writing experience — whether you’re at sea level or on a high-altitude flight.

3. Manufacturing and Cost Efficiency

From a production standpoint, the hole isn’t just functional — it’s economical .

During the injection molding process , molten plastic is injected into a mold to form the cap. The hole:

Reduces the amount of plastic needed

Speeds up cooling time

Makes it easier to eject the cap from the mold

This translates to:

Lower material costs

Faster production

Less waste

In an industry where millions of pens are made daily , even a tiny reduction in plastic per cap adds up to massive savings.

SEE NEXT PAGE

ADVERTISEMENT